Application Areas

Home Page / Roll Hair Applications

Your Reliable Solution Partner in Metal Processing Technologies

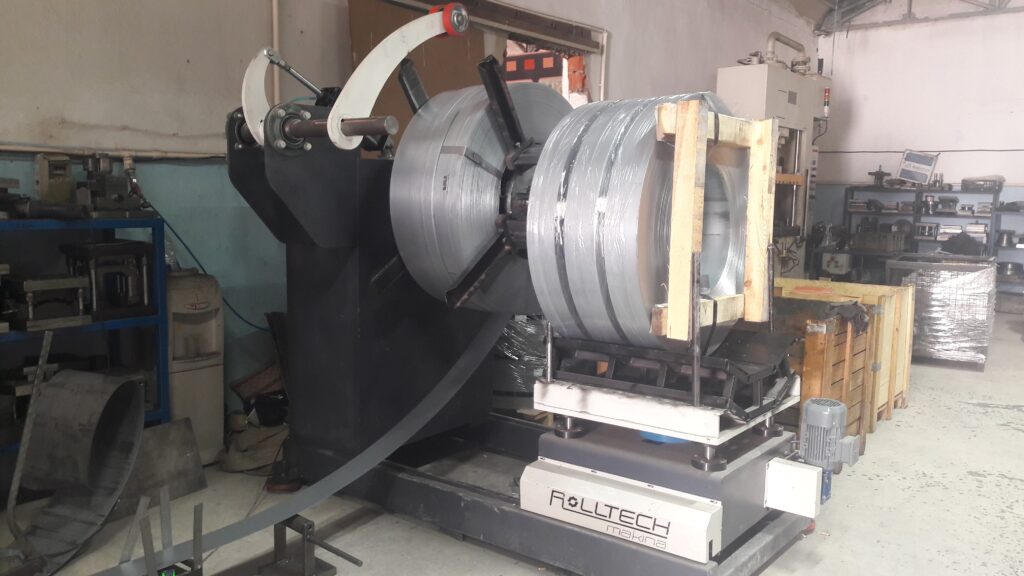

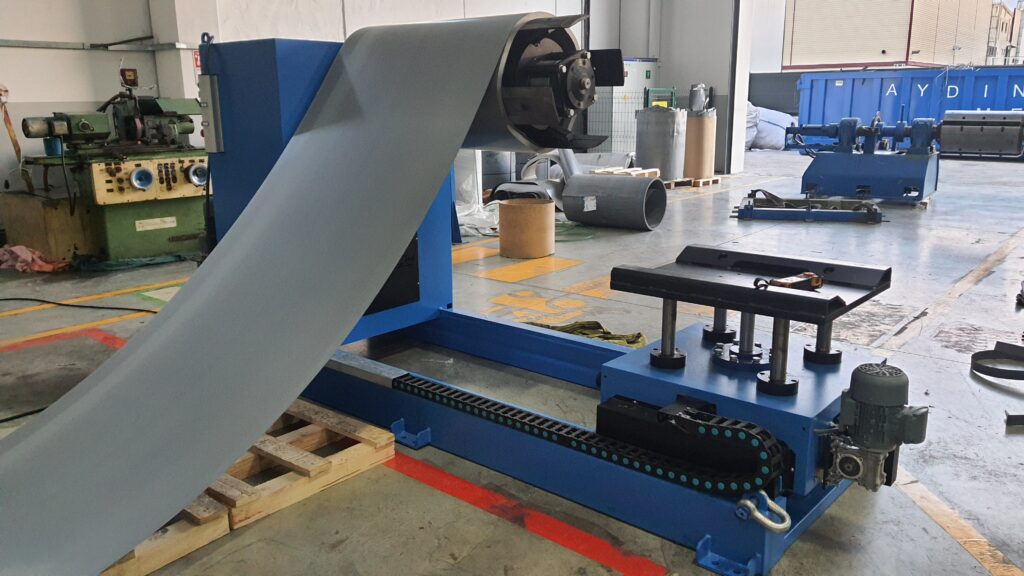

Rolltech decoiler provides fast and efficient processing of sheet materials used in industrial production. With its powerful hydraulic systems and user-friendly design, it increases productivity and provides precise control.

Electrical Panel Manufacturing line

Rolltech Makina offers reliable solutions for industrial electrical panel manufacturing line. Combining modern technology and expertise, Rolltech machines ensure fast and efficient production of electrical panels.

Thanks to their robust construction and user-friendly design, Rolltech machines facilitate operators and optimize production processes. Rolltech Machines are the right choice for those looking for reliability and quality in electrical panel manufacturing.

Contact for detailed information and on-site exploration

Rolltech Decoiling Machines in Radiator Production Line: Increase Your Productivity

Rolltech Machinery stands out in the sector with its decoiling machines used in the radiator production line. With their powerful hydraulic systems and user-friendly designs, Rolltech machines speed up radiator production processes and increase productivity.

In radiator manufacturing, material handling is critical. Rolltech decoilers enable fast and precise processing of sheet materials, thus increasing the efficiency of your production line. They also offer a long-lasting performance thanks to their reliability and durable construction.

Rolltech's decoilers offer an excellent experience to their users. While increasing operational efficiency with its easy operation and fast assembly, it enables you to achieve quality results with its precise control features.

You can optimize your production processes by using Rolltech's reliable and high quality machines in your radiator production line. Contact us for more information and increase productivity with Rolltech.

Solar Energy Panel Profile Production Lines: Quality Solutions with Rolltech Makina

Rapidly developing demands in the solar energy sector bring along the need for high quality and efficiency in solar panel profile production lines. Rolltech Makina specializes in solar energy panel profile production lines and offers pioneering solutions to the sector.

Rolltech's decoilers play an important role in solar panel profile production lines. With their powerful hydraulic systems and user-friendly design, Rolltech machines enable fast and precise processing of sheet materials. This optimizes production processes and raises quality standards.

Rolltech Makina maintains its leading position in the sector for solar energy panel profile production lines. With the reliable and high quality machines we provide to our customers, we ensure sustainable and efficient production processes in the solar energy sector.

By utilizing Rolltech Makina's quality solutions in your solar energy panel profile production lines, you can stand out in the sector and gain a competitive advantage. Contact us for more information and make a difference in the solar energy sector with Rolltech!"

Decoiling Applications in Automotive Supply Industry

The automotive industry is a sector where high quality and precision parts are produced. It is important to process and shape the materials used in the manufacture of these parts. Decoiling machines are an important equipment widely used in the automotive supply industry. Here are the applications of these machines in the automotive supply industry:

Sheet Metal Processing: Sheet metal is often used in the production of automotive parts. Decoilers enable these sheet materials to be stored and processed in rolls. This process plays an important role in the cutting and shaping processes of the materials used in part production.

Precision Cutting: The production of automotive parts requires parts with precise dimensions. Decoilers support the production of precision parts by ensuring that the material is cut to the correct dimensions.

Forming and Bending: Automotive parts often need to be in different shapes and sizes. Decoiling machines enable sheet materials to be bent and shaped into the desired shapes and sizes. This ensures that automotive parts have the desired properties.

Efficiency and Quality: In the automotive supply industry, it is important that production processes are efficient and quality standards are high. Decoiling machines provide an efficient production process, reducing production costs and supporting the production of quality parts.

The use of decoilers in the automotive supply industry enables optimization of production processes and the production of quality automotive parts. These machines are an indispensable tool for manufacturers in the automotive industry to remain competitive and meet customer demands.

Decoiling Applications in Automotive Supply Industry

The automotive industry is a sector where high quality and precision parts are produced. It is important to process and shape the materials used in the manufacture of these parts. Decoiling machines are an important equipment widely used in the automotive supply industry. Here are the applications of these machines in the automotive supply industry:

Sheet Metal Processing: Sheet metal is often used in the production of automotive parts. Decoilers enable these sheet materials to be stored and processed in rolls. This process plays an important role in the cutting and shaping processes of the materials used in part production.

Precision Cutting: The production of automotive parts requires parts with precise dimensions. Decoilers support the production of precision parts by ensuring that the material is cut to the correct dimensions.

Forming and Bending: Automotive parts often need to be in different shapes and sizes. Decoiling machines enable sheet materials to be bent and shaped into the desired shapes and sizes. This ensures that automotive parts have the desired properties.

Efficiency and Quality: In the automotive supply industry, it is important that production processes are efficient and quality standards are high. Decoiling machines provide an efficient production process, reducing production costs and supporting the production of quality parts.

The use of decoilers in the automotive supply industry enables optimization of production processes and the production of quality automotive parts. These machines are an indispensable tool for manufacturers in the automotive industry to remain competitive and meet customer demands.

CTL Series: Rolltech Makina's Complete Line Applications

Rolltech Makina offers industrial solutions in complete line applications with CTL Series. Decoiling, cutting and straightening machines, which are part of this series, are designed to increase production efficiency in the metal industry.

CTL Series machines are characterized by high precision and reliability. By quickly and efficiently uncoiling, cutting and straightening rolls, they save customers time and labor. This increases efficiency in production processes and reduces costs.

Rolltech Makina aims to offer the best performance to customers by using the latest technology in CTL Series machines. With its innovative design and user-friendly interface, it facilitates the work of operators and optimizes production processes.

Offering customizable solutions to customers, Rolltech Makina takes into account the specific requirements for each project and provides the most suitable equipment. Professional engineers work continuously to meet customers' expectations and provide the best solutions.

If you want to optimize your industrial production processes and increase productivity, Rolltech Makina's CTL Series machines can offer ideal solutions for you. Contact us for more information and requests, our expert team is ready to find the most suitable solution for you.

Clip Production Line: High Efficiency and Quality with Rolltech Machine

Clip production line is an important production line used in various industries. These lines enable the production of clips from metal or plastic materials and are widely preferred in assembly and connection processes used in various sectors. Rolltech Makina stands out in the industry by offering innovative solutions for the clip production line.

Rolltech's clip production line solutions aim for high productivity and quality standards. Fast and precise production processes ensure quick response to customers' demands and reduce production costs. Furthermore, thanks to Rolltech's technological innovations, the efficiency and reliability of the clip production line increases.

Rolltech Makina's clip production line solutions offer a wide range of products and customizable design options. In this way, solutions are provided to suit the different needs and demands of customers. Rolltech's expert engineers develop and implement customized solutions taking into account the specific requirements of customers.

Quality, reliability and customer satisfaction are at the forefront among the reasons why Rolltech Makina is preferred for the clip production line. By maintaining its leading position in the sector, Rolltech provides competitive advantage to its customers in clip production line solutions and offers long-term cooperation opportunities.

Tractor Production Supply Industry: Innovation and Quality with Rolltech Makina

Tractor production is an industry that plays an important role in the agriculture and construction sectors and has a wide ecosystem of subsidiary industries. For businesses operating in this sector, it is vital to use high quality and reliable equipment. Rolltech Makina maintains its leading position in the sector by offering innovative solutions for the tractor production sub-industry.

Rolltech's equipment designed specifically for the tractor production sub-industry is focused on reliability, durability and efficiency. Made from high quality materials and equipped with the latest technology, the machines are designed to meet and even exceed customers' expectations.

Rolltech Makina's solutions for the tractor manufacturing supplier industry include decoilers, cutting lines, forming machines and automation systems. This equipment is ideal for processing sheet metal and profiles used in the production of tractor parts.

Rolltech maintains its leading position in the industry by offering customizable solutions according to the needs of its customers. With its expert engineer staff and customer-oriented approach, it carefully evaluates each project and offers the most suitable solution.

Rolltech Makina in the Cooling Systems Sector: Innovation and Reliability

The refrigeration systems sector is a vital sector that is used in a wide range of industries, from industrial plants to the automotive industry. For businesses operating in this sector, it is critical to use high quality and reliable equipment. Rolltech Makina maintains its leading position in the sector by offering innovative solutions for the cooling systems sector.

Rolltech's equipment designed specifically for the cooling systems sector is focused on reliability, durability and efficiency. Made from high quality materials and equipped with the latest technology, the machines are designed to meet and even exceed customer expectations.

Rolltech Makina's solutions for the cooling systems sector include decoilers, cutting lines, forming machines and automation systems. This equipment is ideal for processing sheet metal and profiles used in the production of cooling systems.

Rolltech maintains its leading position in the industry by offering customizable solutions according to the needs of its customers. With its expert engineer staff and customer-oriented approach, it carefully evaluates each project and offers the most suitable solution.

Quality, reliability and customer satisfaction are at the forefront among the reasons why Rolltech Makina is preferred in the cooling systems sector. Rolltech provides competitive advantage to its customers with its experience and expertise in the sector and offers long-term cooperation opportunities.

If you are looking for quality and innovative equipment in the cooling systems sector, Rolltech Makina may be the right address for you. Contact us for more information and requests, our expert team will be happy to provide you with the best service.

Light Steel Production Lines: Rolltech Makina's Innovative Solutions

Light gauge steel production lines play an important role in the production of structural systems used in the construction industry. These lines enable the production of light steel structural elements in a fast, flexible and cost-effective way. Rolltech Makina maintains its leading position in the sector by offering innovative solutions for light steel production lines.

Rolltech's mild steel production lines are manufactured from high quality materials and equipped with the latest technology. Covering precision cutting, forming and welding processes, these lines provide superior performance and efficiency in the production of light steel structural elements.

Rolltech Makina's mild steel production lines are customizable and flexibly designed according to customers' needs. The expert engineering staff carefully evaluates each project and offers the most suitable solution, thus meeting the expectations of the customers.

Innovative technologies and processes in light steel production lines are designed to respond to the fast and dynamic demands of the construction industry. Rolltech Makina continuously continues its R&D efforts to provide its customers with a competitive advantage and support them to stand out in the industry.

If you are in need of mild steel production lines, you can benefit from Rolltech Makina's expertise and experience. Contact us for more information and requests, our expert team will be pleased to offer you the best service.

Ship Supply Industry Cabin Production Lines: Rolltech Makina's Solutions

Ship supply industry cabin production lines play an important role in the production of cabins and interior equipment used in the maritime industry. Rolltech Makina offers specially designed solutions for ship supply industry cabin production lines.

Rolltech Makina's ship supply industry cabin production lines are made of high quality materials and equipped with the latest technology. These lines perform processes such as cutting, shaping, welding and assembly of cabin parts quickly and efficiently.

Ship supply industry cabin production lines are equipped with precision measuring and cutting equipment, which ensures that parts are perfectly matched. In addition, automation technologies reduce labor costs and increase production efficiency.

Rolltech Makina offers customizable solutions for ship supply industry cabin production lines. It stands out with its flexible and modular design to meet the specific requirements of customers. Professional engineers approach each project carefully and offer the most suitable solution.

If you are in need of cabin production lines for the ship supply industry, you can benefit from Rolltech Makina's expertise. Contact us for more information and requests, our expert team is ready to offer you the best service.

Warehouse Shelf Production Lines: Rolltech Makina's Innovative Solutions

Warehouse racking production lines are important equipment that enable the production of various shelving and racking systems used in storage systems. Rolltech Makina offers reliable and innovative solutions for warehouse racking production lines.

Rolltech Makina's warehouse racking production lines are made of high quality materials and equipped with the latest technology. These lines perform operations such as shaping, cutting and assembly of shelf parts of different sizes in a fast, efficient and precise manner.

Reliability and durability are the basic principles of Rolltech Makina's warehouse racking production lines. It is ensured that each part is in perfect harmony and high quality results are achieved.

Rolltech Makina offers customizable solutions to its customers and takes into account the specific requirements for each project. Professional engineers work continuously to meet customers' expectations and provide the best solutions.

If you are in need of warehouse racking production lines, you can benefit from Rolltech Makina's expertise. Contact us for more information and requests, our expert team is ready to provide you with the best service.

Stainless Chimney Production Lines: Rolltech Makina's Reliable Solutions

Stainless chimney production lines play an important role in the production of durable and long-lasting chimneys used in industrial and residential buildings. Rolltech Makina offers reliable and innovative solutions for stainless chimney production lines.

Rolltech Makina's stainless chimney production lines are made of high quality stainless steel and equipped with the latest technology. These lines perform processes such as cutting, shaping, welding and assembly of chimney parts quickly and efficiently.

Reliability and durability are the basic principles of Rolltech Makina's stainless chimney production lines. It is ensured that each part is in perfect harmony and high quality results are achieved.

"Your Stainless Chimneys are Always Safe with Rolltech Makina"

Rolltech Makina offers customizable solutions to its customers and takes into account the specific requirements for each project. Professional engineers work continuously to meet customers' expectations and provide the best solutions.

If you are in need of stainless steel chimney production lines, you can benefit from Rolltech Makina's expertise. Contact us for more information and requests, our expert team is ready to provide you with the best service.

Silicon Steel Sheet Transformer Production Lines: Rolltech Makina's Reliable Solutions

Silicon sheet transformer production lines play an important role in the production of power transformers used in the electrical industry. Rolltech Makina offers reliable and innovative solutions for silicon sheet transformer production lines.

Rolltech Makina's silicon sheet transformer production lines are made of high quality materials and equipped with the latest technology. These lines perform processes such as cutting, shaping, welding and assembly of sheet transformer parts quickly and efficiently.

Reliability and durability are the basic principles of Rolltech Makina's silicon sheet transformer production lines. It is ensured that each part is in perfect harmony and high quality results are achieved.

Rolltech Makina offers customizable solutions to its customers and takes into account the specific requirements for each project. Professional engineers work continuously to meet customers' expectations and provide the best solutions.

If you are in need of silicon sheet transformer production lines, you can benefit from the expertise of Rolltech Makina. Contact us for more information and requests, our expert team is ready to offer you the best service.

Rollform Production Lines: Rolltech Makina's Innovative Solutions

Rollforming production lines are important equipment for shaping various profile and sheet materials used in the metal industry. Rolltech Makina offers reliable and innovative solutions for roll forming production lines.

Rolltech Makina's roll forming production lines are made of high quality materials and equipped with the latest technology. These lines perform processes such as roll forming and profiling of sheet materials of different thicknesses in roll form in a fast, efficient and precise manner.

Reliability and durability are the basic principles of Rolltech Makina's roll forming production lines. It is ensured that each part is in perfect harmony and high quality results are achieved.

Rolltech Makina offers customizable solutions to its customers and takes into account the specific requirements for each project. Professional engineers work continuously to meet customers' expectations and provide the best solutions.

If you are in need of roll forming production lines, you can benefit from the expertise of Rolltech Makina. Contact us for more information and requests, our expert team is ready to offer you the best service.

Automatic Door Production Lines: Rolltech Makina's Innovative Solutions

Rolltech Makina is a well-known brand with more than 15 years of experience in the industrial sector and high quality machines produced in its modern facilities in Bursa since 2014.

Automatic door production lines are one of the most innovative solutions offered by Rolltech Makina. High Efficiency and Precision Rolltech Makina's automatic door production lines offer high efficiency and precision in production processes. Equipped with advanced technology, these lines ensure fast and accurate production of automatic door components. In this way, you will save time and cost while increasing your production capacity. Reliability and Durability Rolltech Makina always prioritizes reliability and durability in its products.

Our automatic door production lines consist of long-lasting and high-performance machines. Each component is manufactured in accordance with quality standards and undergoes rigorous testing. Customizable Solutions Rolltech Makina, which offers solutions suitable for specific requirements for each customer, can customize automatic door production lines according to your needs. Our professional engineer team collaborates with you to complete your projects in the best way and offers the most suitable solutions.

Technological Superiority Rolltech Makina's automatic door production lines incorporate the latest technological developments. Equipped with automatic control systems, precise sensors and efficient production techniques, these lines optimize your production processes and increase quality.

Expanded Rolled Sheet Production Line: Rolltech Machine

Rolltech Makina makes a difference in the industry with its expanded coil sheet production lines that offer high efficiency and precision in industrial production. Produced in modern facilities in Bursa, these lines prioritize quality and reliability while optimizing your production processes. Increase your production capacity and reduce your costs with Rolltech Makina's advanced technology solutions. Contact us for detailed information and customized solutions.

Rolltech's Customer-Centric Future Vision

Customer Oriented Quality Approach

The Rolltech brand places its customers at the center of its quality approach. Customer satisfaction is accepted as the assurance of the future of the holding and all resources are focused on keeping customer satisfaction at the highest level. Rolltech has adopted the principle of providing quality service to customers, working in accordance with international standards and legal regulations, complying with ethical rules, continuously improving quality and being a pioneer in the sector by offering innovative solutions to customer expectations.

High Quality and Continuous Improvement Process

Rolltech prioritizes high quality at every stage of production. Quality control studies are carried out meticulously in all processes from raw material purchase to the final product. In its laboratories, quality control tests and analyzes are carried out with the latest technology devices. In addition, technical support is provided by taking customer feedback into account and the products are delivered to customers in the highest quality.

Since 2014 we have been producing for you

Rolltech focuses on quality and customer satisfaction to help its customers achieve their business goals. The Rolltech brand is the assurance of quality and performance in decoilers.

Above your expectation

Rolltech decoilers have superior accuracy and leveling characteristics to be able to flatten the sheet material in the most precise way. This guarantees quality in the production process.

The ability to process sheet rolls of different sizes and thicknesses is a hallmark of Rolltech decoilers. Their flexibility perfectly adapts to various production needs.

Rolltech machines are made of quality materials and have a robust construction. This means they have a long lifespan and low maintenance requirements, keeping your business running continuously and smoothly.

Rolltech decoilers are characterized by their ability to decoil rolls quickly and efficiently. Their high productivity and performance result in significant time and cost savings in your production processes.

Automatic adjustments and advanced control features enable Rolltech machines to operate more efficiently and consistently. This improves production quality and optimizes operational processes.

Rolltech focuses on quality and customer satisfaction to help its customers achieve their business goals. The Rolltech brand is the assurance of quality and performance in decoilers.